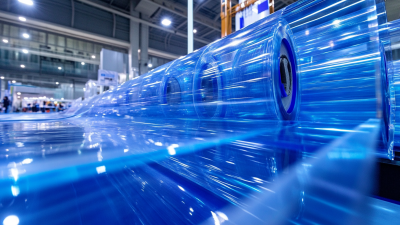

Top 10 Shrink Wrap Film Manufacturers in China at the 137th Canton Fair

The 137th Canton Fair, held recently in Guangzhou, has set new records with an unprecedented number of international buyers attending. This year's fair emphasized the growing demand for various packaging solutions, including the crucial category of Shrink Wrap Film. As businesses worldwide seek efficient and reliable ways to protect and package their products, the spotlight on leading manufacturers of Shrink Wrap Film in China has never been more significant. With a reported intention for export transactions reaching $25.44 billion—a 3% increase compared to previous years—it's clear that the global market is vibrant and ready for quality packaging innovations. This blog will explore the top 10 Shrink Wrap Film manufacturers showcased at the fair, highlighting their contributions to the packaging industry and the ongoing evolution of packaging technologies that cater to diverse business needs.

Read more »

By:Charlotte - June 4, 2025

By:Charlotte - June 4, 2025

Navigating Tariff Challenges: How China's Food Packaging Equipment Surged Despite US-China Trade Tensions

In recent years, the food packaging equipment industry has experienced remarkable resilience, particularly in the face of escalating US-China trade tensions. According to a report by MarketsandMarkets, the global food packaging equipment market is projected to reach $50 billion by 2025, driven by increasing consumer demand for packaged food products. Despite the imposition of tariffs and trade barriers, China's food packaging equipment sector has not only sustained its growth but has also surged ahead, capturing a significant share of the international market. As companies adapt to shifting economic landscapes and seek cost-effective solutions, Chinese manufacturers have leveraged their technological advancements and competitive pricing to position themselves favorably. This blog delves into the strategic maneuvers and innovations that have allowed China's food packaging equipment industry to thrive, even amidst tariff challenges that have deterred other sectors.

Read more »

By:Charlotte - May 30, 2025

By:Charlotte - May 30, 2025

Unlocking Global Opportunities at the 137th Canton Fair with Innovative Shrink Wrap Film Solutions

The 137th Canton Fair has marked a significant milestone in the realm of international trade, drawing an unprecedented number of overseas buyers from 219 countries and regions. As the fair concluded on May 4, 2025, with nearly 288,938 international participants—a remarkable 17.3% increase compared to the previous edition—business opportunities have never been more promising. Among the exhibitors showcasing their innovative solutions, Shrink Wrap Film stood out as a vital product, meeting the diverse packaging needs of various industries. With an intention to export transactions reaching $25.44 billion, businesses are keen to capitalize on the momentum generated by this landmark event. As preparations for the 138th Canton Fair commence, running from October 15 to November 4, companies are encouraged to participate and explore new avenues for growth while leveraging advanced packaging technologies like Shrink Wrap Film to enhance their global outreach.

Read more »

By:Charlotte - May 25, 2025

By:Charlotte - May 25, 2025

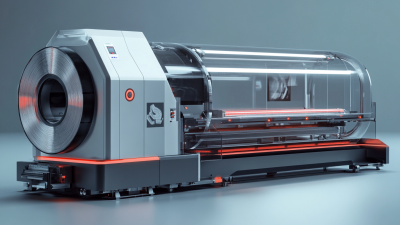

Innovative Options Beyond Tray Sealing Machines for Efficient Packaging Solutions

In today's fast-paced manufacturing environment, efficient packaging solutions are more critical than ever. The global packaging machinery market is projected to reach $50 billion by 2025, with a significant portion attributed to advancements in technologies such as the Tray Sealing Machine. According to a report by MarketsandMarkets, the demand for such machines is driven by increasing consumer preferences for ready-to-eat meals and fresh food products, which require superior sealing capabilities to extend shelf life and enhance presentation. However, as businesses seek to optimize their packaging processes, innovative options beyond the traditional Tray Sealing Machine are emerging. These alternatives not only offer enhanced efficiency and versatility but also cater to the growing demand for sustainable practices in packaging. By exploring these innovative solutions, companies can stay ahead in a highly competitive market while meeting the evolving expectations of consumers.

Read more »

By:Amelia - May 20, 2025

By:Amelia - May 20, 2025

Innovative Approaches to Packaging Machine Integration

In the fast-evolving landscape of manufacturing, the integration of innovative packaging machines has become a crucial factor in enhancing operational efficiency and product quality. According to a report by Smithers Pira, the global market for packaging machinery is projected to reach $55 billion by 2024, driven by the increasing demand for automation and sustainable practices in production lines. As businesses strive to meet consumer expectations for rapid delivery and eco-friendly solutions, the adoption of advanced technologies, such as robotics and IoT-enabled systems, is transforming traditional packaging methods. This blog will explore various cutting-edge approaches to packaging machine integration that not only optimize production processes but also address the growing requirements for flexibility and adaptability in today's competitive market. By embracing these innovative strategies, manufacturers can secure a significant advantage, ensuring that their packaging solutions effectively align with industry trends and customer needs.

Read more »

By:Amelia - May 15, 2025

By:Amelia - May 15, 2025

7 Compelling Benefits of Investing in a Packaging Machine for Your Business

In today’s fast-paced and competitive business landscape, investing in a Packaging Machine has become an essential strategy for companies looking to enhance efficiency and reduce operational costs. According to a report by Smithers Pira, the global packaging machinery market is expected to reach $54 billion by 2026, growing at a compound annual growth rate (CAGR) of 3.2% from 2021. This trend underscores the increasing reliance on automation and advanced packaging solutions, not only to meet consumer demands but also to streamline production processes and ensure product integrity.

As businesses strive to differentiate themselves in the market, the adoption of modern Packaging Machines offers numerous advantages that can significantly impact profitability. From improved accuracy and reduced waste to enhanced speed and scalability, these machines can transform how products are packaged, ultimately driving customer satisfaction and loyalty. In an era where e-commerce continues to expand rapidly, understanding the compelling benefits of investing in packaging machinery is crucial for businesses aiming to thrive in a highly competitive environment.

Read more »

By:Lillian - May 12, 2025

By:Lillian - May 12, 2025

Innovative Strategies for Choosing the Best Tray Sealing Machines in Global Markets

In an increasingly competitive global market, selecting the right equipment can significantly impact operational efficiency and product quality. One of the key pieces of machinery that plays a vital role in packaging is the Tray Sealing Machine. These machines not only enhance shelf life and ensure product safety but also contribute to reducing waste and optimizing resource use. As businesses strive to meet the rising consumer demand for convenience and sustainability, understanding the innovative strategies for choosing the best Tray Sealing Machine has never been more critical.

As technology continues to evolve, the variety of options available for Tray Sealing Machines also expands, presenting a challenge for manufacturers to identify the ideal solution for their specific needs. This blog will explore influential factors to consider when selecting a Tray Sealing Machine, including performance metrics, compatibility with various materials, and the importance of supplier reliability. By leveraging these innovative strategies, businesses can make informed decisions that align with their operational goals and drive success in today’s dynamic marketplace.

Read more »

By:Charlotte - May 10, 2025

By:Charlotte - May 10, 2025

Exploring the Future of Food Packaging Innovations and Their Impact on Global Supply Chains

As the global demand for food continues to rise, the importance of innovative food packaging solutions has never been more critical. According to a report by MarketsandMarkets, the global food packaging market is projected to reach USD 500 billion by 2026, growing at a compound annual growth rate (CAGR) of 5.7% from 2021. This surge is driven by the ever-evolving consumer preferences toward sustainable, convenient, and safe packaging options that not only protect the quality of food but also contribute to minimizing environmental impact. With increasing regulations and a heightened focus on sustainability, food packaging innovations are reshaping how products are packaged, shipped, and ultimately consumed on a global scale.

These innovations are not only transforming the packaging landscape but are also having profound implications for global supply chains. A study by Grand View Research indicates that advancements in smart packaging technologies—such as active and intelligent packaging—will revolutionize food preservation and traceability. By providing real-time information about product conditions, these technologies can enhance safety and reduce waste, improving overall supply chain efficiency. As we delve deeper into the intersection of food packaging innovations and global supply chains, it becomes clear that the future of food packaging is not just about aesthetics, but also about creating a more sustainable and resilient food system.

Read more »

By:Amelia - May 7, 2025

By:Amelia - May 7, 2025

Essential Guide to Choosing the Right Food Packaging Machine for Your Business

In the fast-paced world of food production and distribution, selecting the right Food Packaging Machine is crucial for ensuring efficiency, quality, and safety. As businesses strive to meet consumer demands and regulatory standards, the packaging process becomes a vital component of the overall operation. The right machine not only enhances the shelf life of products but also boosts brand appeal and minimizes waste, contributing to the sustainability goals many companies pursue today.

Choosing the appropriate Food Packaging Machine can seem overwhelming given the myriad of options available on the market. Factors such as type of food, production capacity, and budget all play a significant role in the decision-making process. This essential guide aims to equip businesses with the knowledge needed to navigate through their choices effectively. By understanding the features and functionalities of various packaging machines, companies can make informed decisions that align with their operational needs and future growth.

Read more »

By:Lillian - May 6, 2025

By:Lillian - May 6, 2025

7 Essential Insights for Global Buyers of Industrial Packaging Machines

In today's fast-paced global marketplace, the demand for efficient and reliable Industrial Packaging Machines has never been higher. As businesses strive to streamline their operations and enhance productivity, selecting the right packaging equipment plays a crucial role in maintaining competitiveness and meeting customer expectations. With advancements in technology and increasing market complexity, navigating through the myriad of options can be daunting for buyers. This blog aims to provide valuable insights that will assist global buyers in making informed decisions regarding their industrial packaging needs.

Understanding the key factors that influence the purchase of Industrial Packaging Machines is essential for maximizing investment value and ensuring operational efficiency. From assessing the latest technological innovations to evaluating vendor reliability, prospective buyers must consider various elements before committing to a purchase. In the subsequent sections, we will delve into seven essential insights that can guide global buyers through this critical decision-making process, enabling them to choose the right equipment that aligns with their specific requirements and future growth plans.

Read more »

By:Charlotte - May 2, 2025

By:Charlotte - May 2, 2025

Exploring the Impact of Shrink Wrapping Technology on Packaging Efficiency and Cost Reduction in Global Supply Chains

In recent years, the packaging industry has seen significant advancements in technology, particularly with the introduction of shrink wrapping solutions. According to a report by MarketsandMarkets, the global shrink wrap packaging market is projected to grow from USD 16.29 billion in 2020 to USD 25.02 billion by 2025, at a CAGR of 9.1%. This increase is largely driven by the demand for efficient, secure, and aesthetically pleasing packaging solutions across various sectors, from food and beverage to pharmaceuticals. The Shrink Wrapper has become an essential tool in modern supply chain operations, facilitating not only enhanced product protection during shipping but also streamlined processes that contribute to overall efficiency.

The benefits of using Shrink Wrappers extend beyond just product integrity. A study by Packaging Strategies reveals that companies utilizing shrink wrap technology can achieve up to a 25% reduction in packaging costs due to decreased material usage and labor efficiencies. As businesses strive to adopt more sustainable practices, shrink wrapping also offers the advantage of using recyclable materials that reduce environmental impact. This blog will delve into the transformative role of shrink wrapping technology, exploring its implications for packaging efficiency and cost reduction in global supply chains, ultimately demonstrating why this technology is becoming indispensable in today’s competitive market.

Read more »

By:Lillian - April 30, 2025

By:Lillian - April 30, 2025

Global Market Trends 2025 The Evolution of Fully Automatic Packaging Solutions

As we move towards 2025, the packaging industry is undergoing a remarkable transformation driven by advancements in technology and shifting market demands. The evolution of fully automatic packaging machinery has become a pivotal element in this change, offering manufacturers and businesses unprecedented efficiency, speed, and cost-effectiveness. With consumers increasingly valuing convenience and sustainability, the ability to automate packaging processes not only enhances productivity but also supports the need for eco-friendly solutions.

In this blog, we will explore the emerging global market trends that are shaping the future of fully automatic packaging solutions. From innovative designs and smart technology integration to the rising emphasis on sustainable practices, these trends are redefining how products are packaged and delivered. By examining the latest developments in fully automatic packaging machinery, we aim to provide insights into the opportunities and challenges that lie ahead for businesses in the packaging sector.

Read more »

By:Lillian - April 27, 2025

By:Lillian - April 27, 2025

Future of Wrapping Machines in Manufacturing 2025 Essential Features and Considerations

By 2025, technological advancements and changing consumer demands would continue transforming the manufacturing landscape. One of the important factors associated, among others, is wrapping machines, which is a great boosting tool to productivity and efficiency in packaging processes; within the assumption, these machines also ensure that the products are packaged into good quality while optimizing supply chain operations. Obviously, packaging forms an important part of ensuring product safety in ways that it can be understood from the outside. Future features and practical aspects of wrapping machines are primarily important to manufacturers for maintaining a competitive position in the rapidly changing market.

In the coming years, innovations such as automation, smart technology, and sustainability will alter the operation of wrapping machines. Manufacturers should not only think about the machine, but also how efficient, cost-effective, and environmentally friendly their operations are. Delving into the primary features and considerations for wrapping machines in 2025 shows that one will keep moving even before these developments come into place, preparing manufacturing companies to compete better within an increasingly convoluted industry.

Read more »

By:Lillian - April 24, 2025

By:Lillian - April 24, 2025

2025 Global Trends in Shrink Wrap Machines 5 Key Innovations to Watch

Here machines shrink wraps in packaging efficiency and sustainability, while industries innovate. While looking ahead to 2025, the forecast will reveal transformative trends around which these machines will reorganize their capabilities and applications. The future of shrink wrapping machines promises great transformation through the use of the work of technology, green needs, and continually growing consumer demands.

This blog will address five innovations about machines that shrink wrap products and their prominent roles in different sectors. From increased automation and energy efficiency to material use and smart technologies, these innovations further optimize the packaging process toward the global direction of sustainability. In this article, we look at trends in shrink wrap machines and how businesses can embrace those changes to increase competitiveness.

Read more »

By:Charlotte - April 23, 2025

By:Charlotte - April 23, 2025

How to Choose the Right Food Packaging Equipment for Your Business Needs

The significance of such food packaging equipment is made even stronger with the constant change in the food industry. In fact, according to a recent report published by Grand View Research, by 2024, the global food packaging equipment market would grow to USD 50.3 billion, at a compound annual growth rate of 4.2% through the projection period. This growth trend emphasizes the importance of current packaging technology in extending the shelf life of products, in providing safety for food, as well as meeting consumer demands to their convenience and sustainability choices.

Apart from the much position that every Industrial organization wants to keep up with the changes that affect the industry as a whole, choosing the best Food Packaging Equipment is an important aspect for an organization. Efficient packaging machinery is not only the hallmark of operational efficiency, it also reduces wastes and optimizes costs. In its study, MarketsandMarkets estimates that the increased consumer demand for ready-to-eat foods and government interest in food safety will drive demand for advanced packaging solutions. Therefore, exploring the possibilities and learning how those can be adapted in line with the specific requirements of the company are necessary in order to be competitive in this fast growing market.

Read more »

By:Charlotte - April 21, 2025

By:Charlotte - April 21, 2025