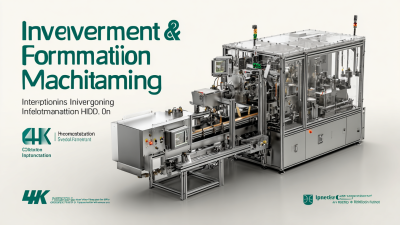

How Automatic Shrink Wrap Machines Revolutionize Packaging Efficiency in Modern Industries

In today's fast-paced industrial environment, the demand for efficient and reliable packaging solutions is paramount. Automatic Shrink Wrap Machines have emerged as a game changer in this realm, significantly enhancing productivity and ensuring product safety. According to a report by Grand View Research, the global shrink wrapping machines market is expected to reach approximately $9.5 billion by 2025, growing at a CAGR of 4.5%. This upward trend underscores the increasing adoption of automatic technologies across various sectors, including food and beverage, pharmaceuticals, and consumer goods. By automating the shrink wrapping process, industries can minimize labor costs, reduce packaging material waste, and improve overall output, making Automatic Shrink Wrap Machines an essential investment for modern businesses looking to stay competitive in the market.

The Evolution of Packaging: A Shift Towards Automation

The evolution of packaging is closely linked to the increasing push towards automation, particularly in modern industries where efficiency and sustainability are paramount. Recent industry events like the FACHPACK Expo 2025 have highlighted how over 1,400 exhibitors are showcasing innovations that reflect this shift. Smart packaging solutions are emerging as a competitive advantage, particularly in sectors like automotive logistics, where traditional packaging methods are being replaced to facilitate automated processes. Research indicates that automated packaging can increase throughput by up to 30% while reducing waste significantly.

As manufacturers embrace advancements in robotics and artificial intelligence, they are not only enhancing production efficiency but also addressing evolving consumer demands. A recent report indicated that automated systems can improve accuracy and safety, which are critical in the highly regulated food sector. The rise of intelligent automation signifies a pivotal transformation where packaging is evolving not just to meet functionality but also compliance, branding, and sustainability goals.

**Tips for Implementing Automation in Packaging:**

- Start with an assessment of your current packaging process to identify bottlenecks that automation can solve.

- Consider investing in modular systems that can be easily upgraded as technology evolves, ensuring long-term viability.

- Train your workforce on new technologies to maximize the potential and minimize resistance to change.

Key Features of Automatic Shrink Wrap Machines for Efficiency

Automatic shrink wrap machines have become game changers in modern packaging efficiency, particularly due to their advanced features that cater to the needs of various industries. One of the key attributes is their high-speed operation, with certain models capable of wrapping up to 40 packs per minute. This significantly reduces labor time and increases production throughput, which is crucial for manufacturers facing high demand. According to a recent report by Grand View Research, the global shrink packaging market is projected to reach USD 30.7 billion by 2025, highlighting the growing reliance on these machines.

Automatic shrink wrap machines have become game changers in modern packaging efficiency, particularly due to their advanced features that cater to the needs of various industries. One of the key attributes is their high-speed operation, with certain models capable of wrapping up to 40 packs per minute. This significantly reduces labor time and increases production throughput, which is crucial for manufacturers facing high demand. According to a recent report by Grand View Research, the global shrink packaging market is projected to reach USD 30.7 billion by 2025, highlighting the growing reliance on these machines.

Another vital feature is their adaptability to different product sizes and shapes. Automatic shrink wrap machines are equipped with adjustable settings and customizable film options, making them versatile for packaging diverse items—from food products to pharmaceuticals. Studies indicate that efficient packaging can reduce material waste by as much as 20%, leading to cost savings and a lower environmental impact.

Tip: When investing in an automatic shrink wrap machine, ensure it comes with a user-friendly interface and robust maintenance support. This can help minimize downtime and maximize productivity. Additionally, consider machines with energy-efficient technology to further enhance your operation's sustainability.

Cost-Benefit Analysis: Investing in Shrink Wrap Technology

Investing in shrink wrap technology offers significant cost benefits for modern industries looking to enhance their packaging processes. Automatic shrink wrap machines increase efficiency by automating the wrapping process, which reduces labor costs and minimizes the time required for packaging. This automation not only streamlines operations but also leads to consistent packaging quality, reducing material waste and potential product damage during transport.

Additionally, the longevity of shrink wrap materials means that businesses can achieve greater savings over time. The initial investment in shrink wrap machinery can yield high returns through improved productivity and lower labor costs. Many companies find that these machines pay for themselves within a short period due to the increased throughput and enhanced operational efficiency. As industries continue to seek ways to optimize their packaging methods, the integration of shrink wrap technology represents a smart move towards a more cost-effective and efficient future.

Real-World Applications: Industries Thriving with Automation

Automatic shrink wrap machines have become vital tools across various industries, significantly enhancing packaging efficiency. For instance, the food and beverage sector relies heavily on these machines to maintain product safety and extend shelf life. According to a report from Smithers Pira, the global shrink wrap market is projected to grow at a CAGR of 4.5% from 2021 to 2026, reflecting its increasing demand in packaging automation. This technology facilitates faster production lines and reduces labor costs, allowing companies to meet rising consumer demands seamlessly.

In the consumer goods industry, companies are reaping the benefits of automation with shrink wrap machines that provide consistent, high-quality packaging. These machines not only improve warehouse efficiency but also minimize product damage during transportation. A study by Mordor Intelligence indicates that over 30% of packaging firms are investing in automation technologies, including shrink wrapping, to enhance their operational efficiencies. This trend underscores the necessity for industries to adapt to changing market conditions and consumer preferences.

Tips: When integrating automatic shrink wrap machines, consider analyzing the return on investment (ROI) for your operation. Additionally, prioritize training your staff on new equipment to ensure smooth transitions and optimal utilization. Regular maintenance of machines can also prevent downtime, maximizing productivity in the long run.

Best Practices for Implementing Shrink Wrap Solutions in Production

Implementing shrink wrap solutions in production environments can lead to significant improvements in efficiency and product protection. According to a report by MarketsandMarkets, the shrink wrap packaging market is projected to reach $17.93 billion by 2025, growing at a compound annual growth rate (CAGR) of 3.7%. This surge highlights the increasing adoption of automated shrink wrap machines, which streamline operations and minimize labor costs. Best practices for implementation include conducting a thorough analysis of product dimensions and weight to optimize machine selection, ensuring compatibility with existing production lines.

Furthermore, regular maintenance and training play a crucial role in maximizing the benefits of shrink wrap technology. A study by the Packaging Machinery Manufacturers Institute (PMMI) found that companies that invest in operator training experience a 30% reduction in downtime. It is essential to establish standard operating procedures that encourage consistent quality and efficiency. Additionally, utilizing advanced features such as multi-pack capabilities and adjustable temperature controls can enhance the wrapping process, leading to superior package integrity and sustainability. Implementing these best practices not only improves packaging operations but also contributes to enhanced product appeal on the shelves.

Related Posts

-

Essential Guide to Choosing the Right Food Packaging Machine for Your Business

-

7 Compelling Benefits of Investing in a Packaging Machine for Your Business

-

Innovative Solutions for Efficient Intermittent Motion Packaging Machinery

-

How to Choose the Right Industrial Shrink Wrap Machine for Your Production Needs: A Data-Driven Approach

-

Choosing the Right Supplier for Your Intermittent Motion Packaging Machine

-

Exploring the Impact of Shrink Wrapping Technology on Packaging Efficiency and Cost Reduction in Global Supply Chains