Ultimate Checklist for Choosing the Best Tray Sealing Machine for Your Business

In today's competitive food packaging industry, selecting the right equipment is crucial for efficiency and quality. The Tray Sealing Machine plays a pivotal role in ensuring products remain fresh while extending their shelf life. According to a report by Grand View Research, the global food packaging machinery market is expected to reach $51.9 billion by 2025, with tray sealing machines witnessing significant demand due to their versatility and reliability. As businesses strive to meet increasing consumer expectations and regulatory demands, adopting advanced packaging solutions like tray sealers is not just an option but a necessity. This blog provides an ultimate checklist to help you navigate the various factors influencing your choice of Tray Sealing Machine, ensuring that you invest wisely in a solution that meets your operational needs and enhances your product's marketability.

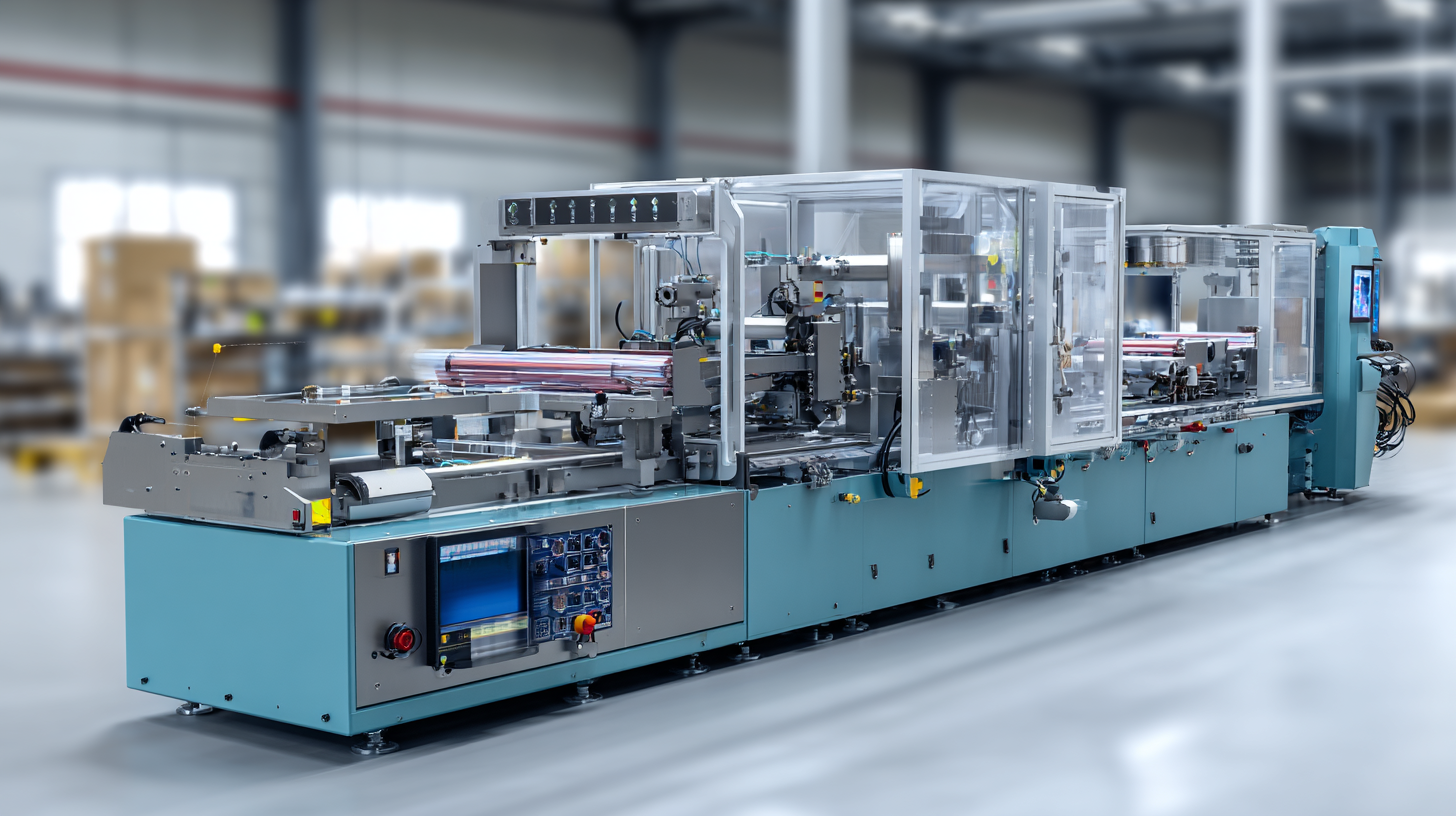

Key Factors to Consider When Selecting a Tray Sealing Machine

When selecting a tray sealing machine for your business, there are several key factors that must be considered to ensure you make the best choice. First, evaluate your production volume and speed requirements. The capacity of the machine should align with your expected output to avoid bottlenecks in your production line. Additionally, assess the materials you will be working with; different machines are designed for specific types of trays and films. Ensuring compatibility will play a crucial role in achieving optimal sealing performance.

Another critical consideration is the machine’s ease of use and maintenance. A user-friendly interface minimizes training time for your staff and increases overall efficiency. Look for machines with automated cleaning features, as this can significantly reduce downtime and prolong equipment life. Furthermore, check the warranty and support services provided by the manufacturer, as reliable service can save your business time and money in the long run. By thoroughly evaluating these factors, you can choose a tray sealing machine that meets your operational needs and contributes to your business's success.

Different Types of Tray Sealing Machines and Their Applications

When selecting a tray sealing machine for your business, it’s essential to understand the different types available and their specific applications. The two primary types are semi-automatic and fully automatic tray sealing machines. Semi-automatic machines are ideal for small to medium-sized operations, providing flexibility and cost-effectiveness. On the other hand, fully automatic machines are designed for high-volume production, enhancing efficiency and reducing labor costs.

Tips: Always consider your production volume when choosing a machine. Evaluate the speed and capabilities of the machine to ensure it meets your operational demands. Additionally, look for machines that can accommodate various tray sizes and materials, as this versatility can strengthen your product line.

Another important type is the vacuum tray sealing machine, which is perfect for perishable products. This technology removes air from the packaging, prolonging shelf life and ensuring freshness. Additionally, MAP (Modified Atmosphere Packaging) tray sealers are ideal for preserving delicate foods like salads and seafood, as they replace the air in the package with a gas mixture tailored to the product being sealed.

Tips: Assess the type of products you plan to package and choose a machine that aligns with your preservation needs. Investing in a machine that offers both vacuum and MAP capabilities can provide a competitive edge by extending your product’s longevity.

Sales Comparison of Different Tray Sealing Machines

Step-by-Step Guide to Evaluating Machine Performance

When evaluating the performance of tray sealing machines for your business, it's critical to assess several key metrics that can significantly impact productivity and product quality. One pivotal factor is the sealing efficiency, which industry's data shows can range from 75% to over 95% depending on the machine's design and technology. Machines equipped with advanced feature sets, such as automatic temperature control and real-time monitoring systems, demonstrate superior sealing capabilities. By ensuring consistent temperature profiles, these machines minimize seal failures, leading to reduced product spoilage and increased customer satisfaction.

Moreover, the speed of the tray sealing process is another essential metric. According to a market report by Smithers Pira, the demand for high-speed packaging solutions has increased by nearly 30% in the last five years. Machines that can achieve upwards of 20 trays per minute not only enhance throughput but also give businesses a competitive edge in efficiency. Additionally, evaluating the machine's ease of operation and maintenance requirements will further influence overall performance. A machine that is user-friendly, reduces downtime, and requires minimal maintenance can significantly boost operational efficiency in the long run.

Importance of After-Sales Support and Maintenance in Tray Sealers

When selecting a tray sealing machine for your business, the importance of after-sales support and maintenance cannot be overstated. A high-quality machine is a significant investment, and ensuring it operates smoothly over time is essential for maintaining productivity and quality.

After-sales support typically includes installation assistance, training for your staff, and readily available customer service. A manufacturer that prioritizes these services demonstrates commitment to customer satisfaction, which is crucial in a competitive market.

Regular maintenance is equally critical. Tray sealers often require routine checks to ensure they are functioning at optimal levels. This can involve replacing worn-out parts, checking for software updates, or cleaning the machine to prevent contamination. A reliable company will provide comprehensive maintenance packages or resources to help businesses manage these tasks effectively. By focusing on after-sales support and maintenance, you can enhance the longevity of your equipment and minimize downtime, leading to increased efficiency and profitability. Making sure these aspects are part of your checklist when choosing a tray sealing machine will ultimately lead to a more successful operation.

Budgeting for Your Tray Sealing Machine: Costs and ROI Analysis

When budgeting for a tray sealing machine, it's crucial to assess not just the initial purchase cost but also the return on investment (ROI) over time. According to a report by Smithers Pira, the global market for tray sealing machines is expected to grow at a CAGR of 5.2%, indicating a robust demand. This growth suggests that investing in a quality machine can yield significant returns as more businesses seek efficient, high-quality packaging solutions. Remember to factor in additional costs such as maintenance, training, and possible upgrades when calculating your total budget.

Tip: Always conduct a cost-benefit analysis to determine how long it will take for the machine to pay for itself. A well-chosen tray sealing machine can reduce packaging costs by as much as 20%, improving overall profit margins. Also, consider the machine's efficiency. Data indicates that high-performance models can increase production speed by over 30%, which can greatly impact your bottom line.

In evaluating the ROI, look at factors like reduced waste, enhanced shelf-life of products, and improved customer satisfaction. A recent study by Packaging Strategies highlighted that products with superior packaging can see a price premium of 10-15%, underscoring the importance of investing in quality machinery that meets industry standards.