Essential Guide to Choosing the Right Food Packaging Machine for Your Business

In the fast-paced world of food production and distribution, selecting the right Food Packaging Machine is crucial for ensuring efficiency, quality, and safety. As businesses strive to meet consumer demands and regulatory standards, the packaging process becomes a vital component of the overall operation. The right machine not only enhances the shelf life of products but also boosts brand appeal and minimizes waste, contributing to the sustainability goals many companies pursue today.

Choosing the appropriate Food Packaging Machine can seem overwhelming given the myriad of options available on the market. Factors such as type of food, production capacity, and budget all play a significant role in the decision-making process. This essential guide aims to equip businesses with the knowledge needed to navigate through their choices effectively. By understanding the features and functionalities of various packaging machines, companies can make informed decisions that align with their operational needs and future growth.

Understanding Different Types of Food Packaging Machines and Their Applications

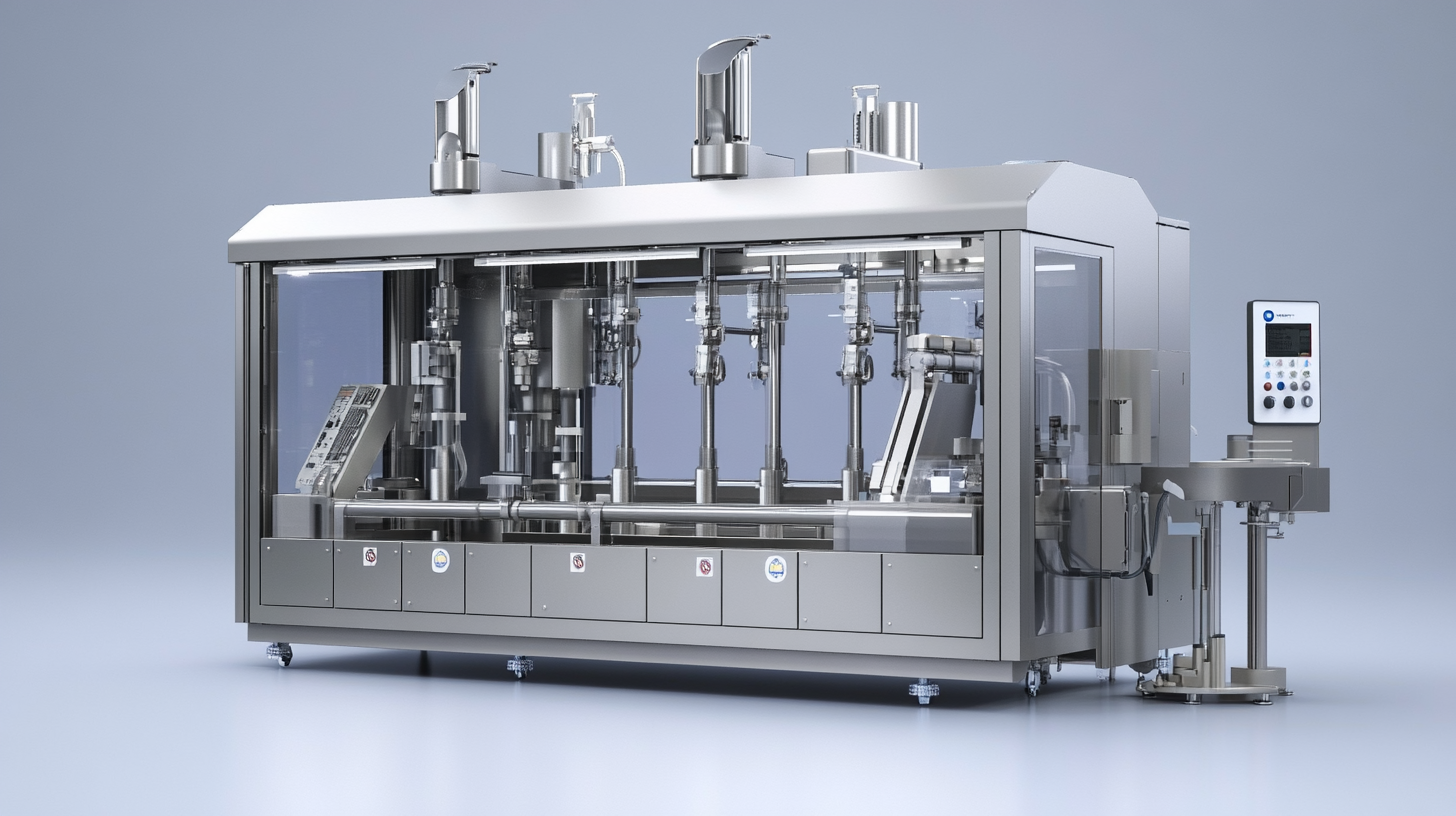

When it comes to selecting the right food packaging machine for your business, understanding the various types and their applications is vital for improving efficiency and meeting consumer demands. Food packaging machines vary greatly in type, including vertical and horizontal form-fill-seal machines, tray sealers, vacuum packaging devices, and labeling machines, each serving a unique purpose in the packaging process. Vertical form-fill-seal machines are designed for products like grains and snacks, efficiently filling and sealing bags in one continuous cycle. In contrast, tray sealers are perfect for fresh produce and meats, ensuring that items are securely packaged while maintaining their freshness. Incorporating artificial intelligence (AI) into the selection and operation of food packaging machines can significantly enhance productivity and quality control. AI can provide real-time data analytics, allowing businesses to monitor machine performance, optimize production lines, and reduce downtime. For instance, machine learning algorithms can predict when a machine requires maintenance, thereby avoiding unexpected failures and ensuring a seamless packaging process. Additionally, AI-driven systems can help in customizing packaging options based on consumer preferences, enabling companies to adapt quickly to market trends and enhance customer satisfaction. Moreover, automated labeling machines, bolstered by AI, can ensure that products are labeled accurately and consistently, which is crucial for compliance in the food industry. This not only streamlines the packaging process but also minimizes human error. As the food packaging landscape continues to evolve, understanding the different types of machines and leveraging technology like AI will be key to staying competitive and meeting the demands of the market.

Key Factors to Consider When Choosing a Food Packaging Machine for Your Business

When selecting the right food packaging machine for your business, several key factors should be considered to ensure you meet both operational needs and market demands. First and foremost is the type of food product you are packaging. Different products require specific packaging solutions; for instance, packaging for baked goods differs substantially from that for meats or dairy products. Understanding the unique requirements of your product, including moisture levels and temperature sensitivities, will guide your decision.

Another critical factor is the material of the packaging. The food packaging market is increasingly leaning towards sustainability, with materials such as biodegradable plastics, paper, and aluminum gaining prominence. Evaluate the pros and cons of each material type not only in terms of cost but also their impact on food safety and shelf life. It's essential to strike a balance between functionality, sustainability, and cost-effectiveness.

Moreover, consider the machine's scalability and flexibility. As your business grows, your packaging needs may evolve, necessitating machines that can adapt to different products and production volumes. Advanced automation features can significantly enhance efficiency, reduce labor costs, and minimize human error. By prioritizing these factors, you will be well-equipped to choose a food packaging machine that aligns with your business goals and market trends.

Analyzing Industry Trends and Innovations in Food Packaging Technology

The food packaging industry is set to witness remarkable changes in the coming years, driven by shifting consumer preferences and advancements in technology. According to projections, the food technology market will surpass $210.9 billion in 2024, with a compound annual growth rate (CAGR) of approximately 8.2% from 2025 to 2034. This growth is largely attributed to innovations that cater to evolving health-conscious consumer demands and the desire for sustainable packaging solutions.

In the beverage sector, insights reveal a growing trend towards aesthetically pleasing and innovative packaging designs. The beverage packaging market is expected to reach $167.9 billion in 2024, driven by a CAGR of 5.3% from 2025 to 2034. Consumers are driven not only by functionality but also by the visual appeal of the packaging, indicating a shift towards designs that enhance brand identity while aligning with sustainability values.

Vacuum packaging is gathering momentum, showing increasing market demand closely aligned with the broader health trends. The analysis indicates that flexible packaging solutions, including vacuum options, are essential for preserving freshness and extending the shelf life of products. As businesses assess their packaging needs, embracing these innovations can significantly enhance their competitive edge in an increasingly evolving market landscape.

With the rapid development in the food packaging machinery segment, businesses must carefully evaluate their options based on emerging technologies and industry trends to ensure they are meeting consumer expectations while optimizing operational efficiency.

Cost-Effectiveness: Balancing Initial Investment and Long-Term Savings

When considering a food packaging machine for your business, cost-effectiveness is a crucial factor that cannot be overlooked. Initially, the investment in high-quality machinery may seem daunting; however, understanding the long-term savings it can bring is essential for making a strategic decision. A well-chosen packaging machine can significantly reduce labor costs and increase production efficiency, leading to enhanced profitability over time.

Investing in an advanced food packaging solution often translates to better product protection and longer shelf life. This not only minimizes waste due to spoilage but also boosts customer satisfaction, as consumers receive fresher and more appealing products. Furthermore, modern machines often come equipped with features that enhance versatility, allowing businesses to adapt to varying product lines and consumer demands without necessitating significant additional investments.

Moreover, factors to consider include maintenance costs and operational efficiency. While opting for a lower-priced machine might seem appealing initially, it can lead to higher costs down the line due to increased downtime and frequent repairs. By focusing on finding a balanced solution that emphasizes quality, your business can ensure that the initial investment leads to cumulative savings over its operational lifespan, thus maximizing your overall return.

Importance of Compliance with Food Safety Regulations in Packaging Solutions

In the food packaging industry, compliance with food safety regulations is not just a legal requirement; it is a crucial factor that can significantly influence the success of a business. According to a report by the Food and Drug Administration (FDA), over 48 million people in the United States suffer from foodborne illnesses each year, underscoring the importance of safe packaging practices. Businesses must prioritize adherence to regulations such as the Food Safety Modernization Act (FSMA), which mandates that food packaging operations maintain stringent hygiene and safety standards throughout the supply chain.

Packaging materials and machinery play a significant role in ensuring food safety. The use of food-grade materials, which meet specific safety standards, is essential to prevent contamination and maintain product integrity. The global food packaging market is projected to reach $500 billion by 2024, driven by increasing consumer awareness of food safety. Companies that invest in advanced packaging solutions not only enhance their compliance efforts but also build consumer trust. According to a study by the Institute of Packaging Professionals, about 61% of consumers are likely to choose products based on their packaging, highlighting the direct correlation between packaging compliance and consumer choice.

Moreover, choosing the right food packaging machine is vital for maintaining regulatory compliance. Machines that facilitate cleanliness, minimize human contact, and employ technology such as track-and-trace capabilities are instrumental in adhering to safety standards. According to a report from the Packaging Association, 78% of companies that have upgraded to modern packaging machinery saw a reduction in compliance-related issues. This underscores the critical need for businesses to focus on not only the efficiency of packaging processes but also on ensuring safety and compliance to thrive in the competitive food industry.