What is Fully Automatic Packaging Machinery and How Does It Transform Production Efficiency?

In today's fast-paced manufacturing environment, the demand for efficiency and precision is greater than ever, leading to the widespread adoption of Fully Automatic Packaging Machinery. According to a recent report by Research and Markets, the global packaging machinery market is projected to reach $57 billion by 2024, driven by the increasing need for automation and cost-effective solutions in various industries. Fully Automatic Packaging Machinery significantly enhances production efficiency by minimizing labor involvement and reducing the probability of human error, which can impact product quality and safety. As industries strive for lean operations, these advanced machines not only streamline packaging processes but also improve throughput and consistency, ultimately contributing to a rapid return on investment. Understanding the features and benefits of Fully Automatic Packaging Machinery can thus empower businesses to transform their production capabilities and maintain competitiveness in an evolving marketplace.

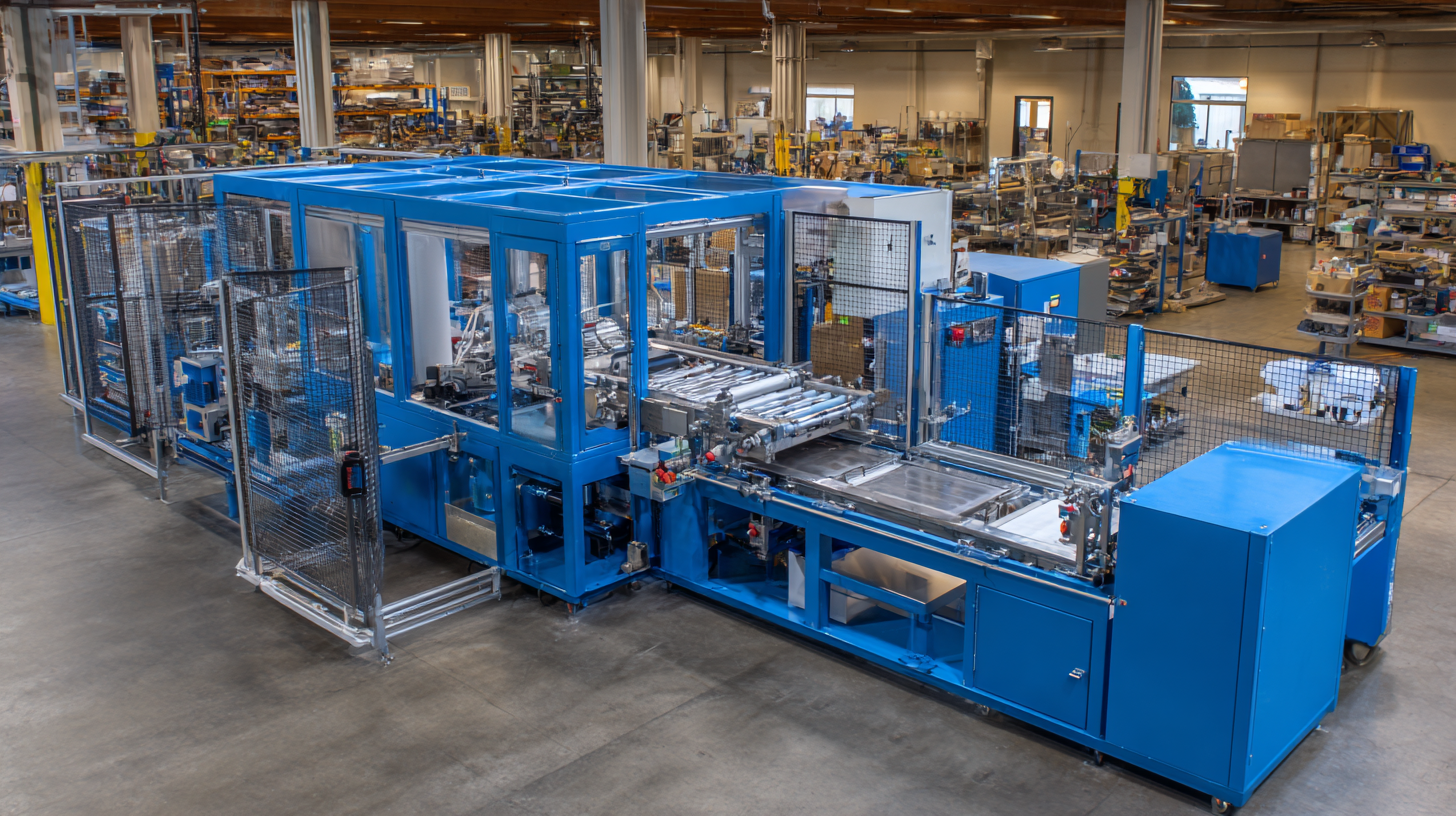

Understanding Fully Automatic Packaging Machinery: Key Features and Components

Fully automatic packaging machinery is revolutionizing production efficiency across various industries by streamlining processes and minimizing manual labor. Key features of this machinery include

high-speed operation,

precise packaging, and integration of advanced technologies such as robotics and AI. For instance, the global modular packaging equipment market size is projected to grow from

USD 15.83 billion in 2025 to around

USD 25.00 billion by 2034, indicating a robust demand for automated solutions that enhance operational productivity.

In addition, aspects such as

energy efficiency and

sustainability are becoming increasingly critical in the packaging sector. Automated machines not only accelerate production but also support companies in reducing waste and improving resource management. For example, the global vacuum packing machines market is anticipated to grow at a

CAGR of 5.1% from 2025 to 2034, underscoring a shift towards machinery that contributes to sustainable practices.

Tips: When investing in fully automatic packaging systems, consider the machine's scalability to meet future demands. Additionally, prioritize equipment with robust maintenance support to ensure long-term operational efficiency. Always evaluate the total cost of ownership, factoring in service, parts, and training for optimal ROI.

The Role of Automation in Enhancing Production Efficiency and Consistency

Fully automatic packaging machinery significantly transforms production efficiency by streamlining various processes. With advanced automation technology, these machines perform complex tasks such as filling, sealing, and labeling at high speeds and consistency, reducing the reliance on manual labor. The integration of robotics and smart controls allows for quick adjustments to different product specifications, leading to minimal downtime and enhanced workflow.

**Tips:** To maximize the benefits of fully automatic packaging machinery, ensure regular maintenance and updates to the software systems. This will help in maintaining optimal performance and preventing costly breakdowns. Additionally, investing in employee training on how to operate and troubleshoot these machines can lead to better efficiency and fewer errors in the production line.

Automation not only boosts productivity but also enhances product quality through precise operations with little variance. This consistency helps companies meet regulatory standards and customer expectations, fostering brand loyalty. By adopting automation, organizations can focus on innovation and expansion, which further contributes to their competitive edge in the market.

**Tips:** Always assess your production line needs and select machinery that can be easily integrated into your existing systems. This ensures a smoother transition and better overall results in production efficiency.

Cost-Benefit Analysis: Investing in Fully Automatic Packaging Solutions

Investing in fully automatic packaging solutions can yield significant cost savings for manufacturers. These advanced machines streamline operations by reducing labor costs, minimizing human error, and maximizing production speeds. By automating the packaging process, companies can reallocate their workforce to more strategic roles, enhancing overall productivity. Moreover, a fully automatic system can operate continuously, leading to higher output and the ability to meet increasing consumer demand without the need for additional shifts or overtime.

On the flip side, the initial cost of purchasing fully automatic packaging machinery can be daunting for some businesses. However, the long-term financial benefits often outweigh these upfront expenses. A comprehensive cost-benefit analysis typically reveals that the increased efficiency and output levels lead to a quicker return on investment. Furthermore, as these systems improve product consistency and reduce waste, companies find themselves benefiting not only in terms of cost savings but also enhanced product quality, helping to build brand reputation and customer loyalty.

Innovative Technologies Behind Fully Automatic Packaging Systems

Fully automatic packaging machinery plays a pivotal role in modern manufacturing by incorporating advanced technologies that enhance production efficiency. According to a report by MarketsandMarkets, the global packaging machinery market is expected to grow from $45.5 billion in 2021 to $63.5 billion by 2026, reflecting a CAGR of 7.7%. This growth is largely driven by innovations such as robotic automation, artificial intelligence, and IoT integration in packaging systems. These technologies enable manufacturers to streamline their operations, minimize waste, and reduce labor costs significantly.

One of the most notable technological advancements is the integration of artificial intelligence in packaging machinery. AI-powered systems can analyze vast amounts of data to optimize packaging processes, enhancing speed and accuracy. A study by the International Society of Automation highlights that implementing AI can lead to a 30% increase in operational efficiency by predicting maintenance needs and reducing downtime. Furthermore, the incorporation of IoT connectivity allows for real-time monitoring and diagnostics, providing manufacturers with invaluable insights that lead to more informed decision-making. These innovations are not only transforming how products are packaged but also setting new industry standards for efficiency and sustainability.

Real-World Applications and Success Stories of Fully Automatic Packaging Machinery

Fully automatic packaging machinery has revolutionized production processes across various industries. For instance, in the food sector, companies like Nestlé have implemented fully automatic systems that boost efficiency by up to 30%. According to a report by Smithers Pira, the global packaging machinery market is projected to grow at a CAGR of 3.9% from 2020 to 2025, driven by the increasing demand for efficient, sustainable, and flexible packaging solutions.

Real-world applications illustrate the transformative power of this technology. Beverage manufacturers, such as Coca-Cola, utilize fully automatic lines that enhance throughput and reduce labor costs significantly. These automated systems not only enhance consistency but also minimize waste, aligning with industry trends towards sustainability. Furthermore, pharmaceutical companies are leveraging advanced packaging machines to ensure compliance with stringent regulations while increasing production speed, thus meeting the urgent demands of the market effectively.

The integration of fully automatic machinery is not just a trend; it has become a strategic necessity for businesses aiming to improve production efficiency and maintain competitive advantage.

Related Posts

-

Top Strategies for Optimizing Your Packaging Equipment Efficiency

-

Innovative Approaches to Packaging Machine Integration

-

Unlocking Efficiency with Semi Automatic Packaging Machine Advantages

-

Global Market Trends 2025 The Evolution of Fully Automatic Packaging Solutions

-

Innovative Strategies for Choosing the Best Tray Sealing Machines in Global Markets

-

Navigating Tariff Challenges: How China's Food Packaging Equipment Surged Despite US-China Trade Tensions