Innovative Options Beyond Tray Sealing Machines for Efficient Packaging Solutions

In today's fast-paced manufacturing environment, efficient packaging solutions are more critical than ever. The global packaging machinery market is projected to reach $50 billion by 2025, with a significant portion attributed to advancements in technologies such as the Tray Sealing Machine. According to a report by MarketsandMarkets, the demand for such machines is driven by increasing consumer preferences for ready-to-eat meals and fresh food products, which require superior sealing capabilities to extend shelf life and enhance presentation. However, as businesses seek to optimize their packaging processes, innovative options beyond the traditional Tray Sealing Machine are emerging. These alternatives not only offer enhanced efficiency and versatility but also cater to the growing demand for sustainable practices in packaging. By exploring these innovative solutions, companies can stay ahead in a highly competitive market while meeting the evolving expectations of consumers.

Exploring Alternative Packaging Technologies to Tray Sealing Machines

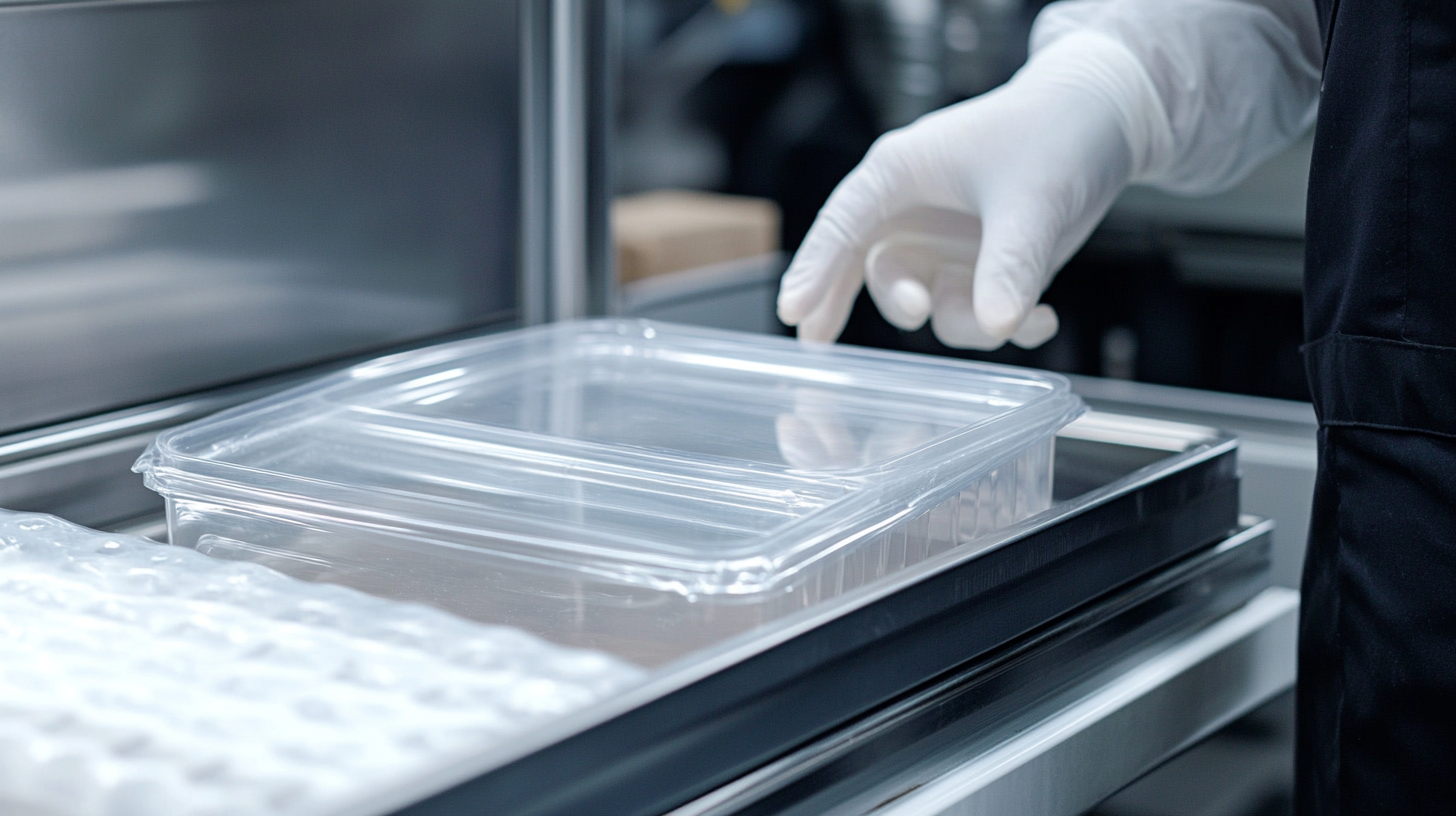

The packaging industry is constantly evolving, driven by the need for efficiency and sustainability. While tray sealing machines have long been a standard choice for many businesses, innovative packaging technologies are emerging that offer viable alternatives. One such option is vacuum packaging, which effectively extends the shelf life of products by removing air and preventing spoilage. This method not only preserves food quality but also reduces waste, making it an attractive alternative for environmentally conscious companies.

Another promising technology is thermoforming, which allows for the creation of custom packaging that perfectly fits a product's shape. This approach not only enhances product presentation but also optimizes space during transport, resulting in lower shipping costs. Additionally, advances in flexible packaging, such as biodegradable materials, offer companies a way to reduce their environmental footprint while maintaining product integrity. By exploring these innovative options, businesses can stay competitive in a rapidly changing marketplace, improve operational efficiency, and meet the increasing consumer demand for sustainable solutions.

The Benefits of Vacuum Packaging for Shelf Life Enhancement

Vacuum packaging has become increasingly popular as a method for enhancing shelf life across various industries. By removing air from the packaging, this technique significantly slows down the oxidation process and the growth of spoilage-causing microorganisms. This ensures that products such as food, pharmaceuticals, and electronics remain fresh and functional for an extended period. Companies are now recognizing that vacuum packaging not only preserves product integrity but also reduces waste, leading to cost savings and improved sustainability.

When considering vacuum packaging, here are a few tips to enhance your packaging process. Firstly, invest in high-quality materials that are specifically designed for vacuum applications. This ensures a better seal and reduces the risk of punctures. Secondly, always adjust the vacuum settings according to the type of product being packaged; delicate items may require a gentler approach to avoid damage. Lastly, consider including desiccants in the packaging to absorb moisture, further extending shelf life and maintaining product quality.

Innovative alternatives to traditional packaging techniques, such as vacuum packaging, are making waves in the industry. By leveraging these solutions, businesses can not only optimize product longevity but also cater to the increasing demand for high-quality and sustainable packaging options.

Understanding the Role of Modified Atmosphere Packaging in Food Preservation

Modified Atmosphere Packaging (MAP) has emerged as a vital technology in food preservation, offering an innovative solution to extend the shelf life of a wide range of products. With the global MAP market projected to grow at a rate of 7.94% through the end of the decade, it signifies a rising recognition of its role in maintaining food quality. MAP works by altering the composition of gasses surrounding the food, effectively slowing down the growth of spoilage organisms and delaying oxidation processes. This technology not only enhances freshness but also reduces food waste, addressing an ongoing concern in the modern food industry.

Recent advancements in packaging materials—particularly biobased and biodegradable polymers—illustrate a shift towards sustainable practices. These innovations align with increasing consumer demand for eco-friendly options without compromising functionality. Additionally, modeling tools are being developed to evaluate the environmental impact of various packaging methods, thereby enhancing decision-making in food preservation strategies. Importantly, MAP also plays a role in pest control, aiding in the protection of stored products from damage, further highlighting its multifaceted benefits in food packaging solutions.

Innovative Solutions: Flexible Packaging Systems for Diverse Products

As the demand for efficient packaging solutions continues to grow, businesses are increasingly exploring flexible packaging systems that cater to a diverse range of products. These innovative solutions not only enhance product protection but also offer great adaptability in design and functionality, allowing companies to meet consumer preferences more effectively. By incorporating advanced materials and production techniques, manufacturers can create packages that are lightweight yet robust, extending shelf life while minimizing waste.

Flexible packaging systems are particularly advantageous for products that necessitate special handling and preservation methods. For instance, items like fresh produce, snacks, and liquids benefit from packaging that can conform to varying shapes and sizes, ensuring convenience and reducing transportation costs. Moreover, the integration of smart packaging technologies can provide real-time information about product freshness, enhancing the consumer experience. With such versatility, brands are empowered to innovate and differentiate themselves in a competitive market, making flexible packaging an essential component of modern packaging strategies.

The Future of Eco-Friendly Packaging: Biodegradable and Compostable Materials

The future of packaging is undeniably leaning towards eco-friendly solutions, particularly biodegradable and compostable materials. As consumers become more environmentally conscious, businesses are realizing the importance of adopting materials that not only reduce waste but also minimize their carbon footprint. These innovative materials break down organically, returning nutrients to the soil, and help combat the global issue of plastic pollution.

When considering a shift to eco-friendly packaging, businesses can benefit from some practical tips. First, conduct a thorough assessment of your current materials and evaluate the impact of transitioning to biodegradable options. This can involve working closely with suppliers who specialize in sustainable materials to find the right fit for your product. Secondly, educate your consumers on the benefits of choosing biodegradable packaging; clear messaging can enhance customer loyalty and encourage more responsible purchasing behaviors.

Additionally, exploring compostable options can further elevate your sustainability efforts. Compostable materials decompose faster than traditional plastics and require specific conditions to break down completely. By incorporating compostable packaging, you not only enhance the brand's eco-image but also contribute positively to waste management practices. Engaging with local composting facilities can also create a community-driven approach to sustainability.