Innovative Approaches to Packaging Machine Integration

In the fast-evolving landscape of manufacturing, the integration of innovative packaging machines has become a crucial factor in enhancing operational efficiency and product quality. According to a report by Smithers Pira, the global market for packaging machinery is projected to reach $55 billion by 2024, driven by the increasing demand for automation and sustainable practices in production lines. As businesses strive to meet consumer expectations for rapid delivery and eco-friendly solutions, the adoption of advanced technologies, such as robotics and IoT-enabled systems, is transforming traditional packaging methods. This blog will explore various cutting-edge approaches to packaging machine integration that not only optimize production processes but also address the growing requirements for flexibility and adaptability in today's competitive market. By embracing these innovative strategies, manufacturers can secure a significant advantage, ensuring that their packaging solutions effectively align with industry trends and customer needs.

Emerging Trends in Packaging Machine Integration for Enhanced Efficiency

As industries strive for increased efficiency, the integration of packaging machines has emerged as a pivotal trend. Recent reports indicate that the global packaging machinery market is projected to reach $50 billion by 2026, showcasing a compound annual growth rate (CAGR) of 4.2% from 2021 to 2026. This surge underscores the pressing need for innovative solutions that enhance productivity and streamline operations.

One of the most promising trends is the adoption of IoT-enabled packaging machinery. According to a study by Smithers Pira, IoT connectivity in packaging can result in a 20% reduction in operational costs and a 30% increase in productivity. By leveraging real-time data analytics, manufacturers can optimize maintenance schedules and reduce downtime, ensuring that packaging lines operate at peak efficiency. Furthermore, the integration of machine learning algorithms helps predict potential bottlenecks, allowing for proactive adjustments in production processes.

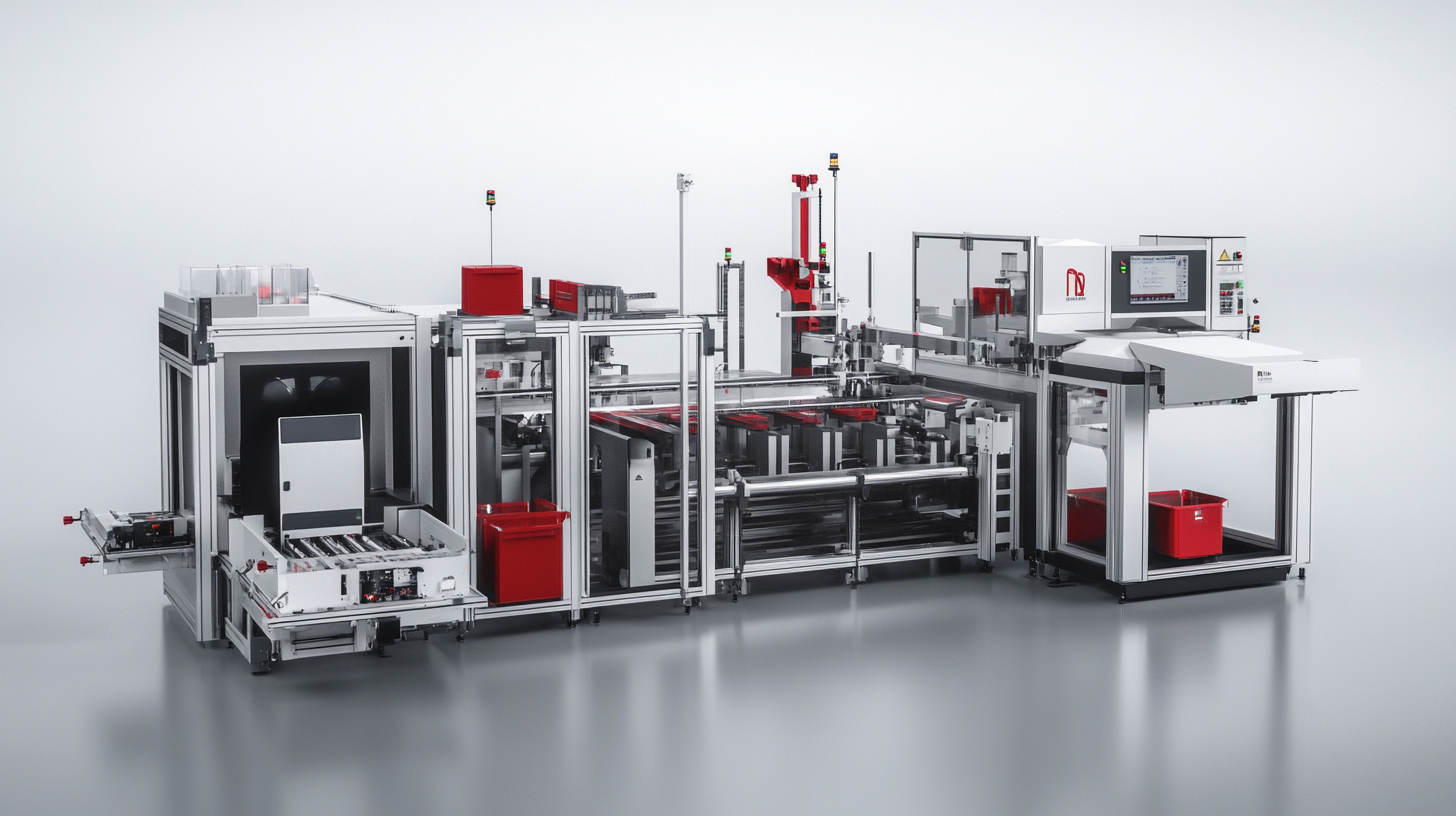

Another significant trend is the move towards modular packaging systems. This flexibility enables manufacturers to customize their production lines according to diverse product requirements without extensive overhauls. A report by MarketsandMarkets notes that modular machines can reduce lead times by up to 50% and facilitate quicker responses to market changes. As companies continue to prioritize speed and adaptability, the innovative integration of packaging machines will be essential to navigating the complexities of modern supply chains.

Leveraging IoT Technology to Optimize Packaging Operations and Workflow

The integration of Internet of Things (IoT) technology into packaging operations is revolutionizing the industry, optimizing workflows beyond traditional methods. By embedding sensors and smart devices into packaging machines, manufacturers can monitor real-time data, allowing them to adjust parameters dynamically for maximum efficiency. This connectivity enables predictive maintenance, reducing downtime and ensuring machines operate at peak performance.

Moreover, IoT technology facilitates seamless communication across the supply chain. Packaging machines equipped with IoT capabilities can share data with inventory management systems, ensuring that supply levels are always aligned with production demands. This synergy not only streamlines processes but also enhances decision-making, leading to reduced waste and improved resource allocation. As a result, businesses can achieve a more agile manufacturing environment, responding swiftly to changing market needs while maintaining high standards of quality and efficiency.

Embracing these innovative approaches to packaging machine integration will not only optimize operations but also drive competitive advantage in a fast-evolving market landscape. The future of packaging lies in smart solutions that leverage IoT technology to create intelligent, adaptive systems capable of transforming how products are delivered to consumers.

The Role of Automation in Streamlining Packaging Machine Integration Processes

Automation plays a crucial role in streamlining packaging machine integration processes, enhancing efficiency and reducing operational costs. According to a recent report by the Packaging Machinery Manufacturers Institute (PMMI), nearly 70% of manufacturers are investing in automation to improve their packaging lines. The integration of automated systems not only minimizes manual intervention but also accelerates the overall production cycle, allowing businesses to respond more swiftly to market demands.

Moreover, the adoption of advanced automation technologies, such as robotics and AI-driven systems, empowers packaging operations to achieve unparalleled precision and consistency. A study by Research and Markets predicts that the automated packaging market will grow at a compound annual growth rate (CAGR) of 14.92% from 2021 to 2028, highlighting a significant trend toward smarter packaging solutions. This shift not only enhances productivity but also significantly improves safety standards by reducing the potential for human error in packaging processes.

As companies continue to adapt to evolving consumer preferences and tighter deadlines, leveraging automation in packaging machine integration proves to be an essential strategy. By harnessing data analytics and real-time monitoring, organizations can gain valuable insights into their operations, further optimizing the integration process and boosting overall competitiveness in the packaging sector.

Case Studies: Successful Packaging Machine Integration in Various Industries

In the fast-evolving landscape of manufacturing, successful packaging machine integration has emerged as a pivotal focus for various industries. One notable case study comes from the food and beverage sector, where a mid-sized company implemented an advanced automated packaging line that not only streamlined their processes but also minimized waste. This integration involved synchronizing their bagging, filling, and labeling machinery, resulting in a 30% increase in production efficiency. Real-time data analytics were also leveraged to monitor machinery performance, allowing for proactive maintenance and reducing downtime.

Another impressive example can be found in the cosmetics industry, where a leading brand integrated state-of-the-art robotic solutions to enhance their packaging operations. By combining high-speed conveyors with precision robotics, they managed to reduce packaging errors significantly and improve throughput. The integration also allowed for greater flexibility in production, enabling the company to quickly adapt to changing market demands and introduce new product lines without extensive delays. These case studies illustrate how embracing innovative approaches to packaging machine integration can drive efficiency and adaptability across various sectors.

Innovative Approaches to Packaging Machine Integration - Case Studies

| Industry | Company | Integration Approach | Outcome |

|---|---|---|---|

| Food & Beverage | ABC Food Co. | Automated Packaging Line | Increased efficiency by 30% |

| Pharmaceutical | XYZ Pharma | Modular Integration | Reduced downtime by 25% |

| Cosmetics | Beauty Corp | Smart Technology Integration | Enhanced product traceability |

| Electronics | Gadget Inc. | Flexible Manufacturing Systems | Improved production cycle time |

| Consumer Goods | Home Essentials | Integrated Software Solutions | Increased throughput by 40% |

Future Outlook: Innovations Shaping the Next Generation of Packaging Solutions

As the packaging industry evolves, the integration of innovative technologies is transforming the landscape of packaging solutions. Companies are increasingly seeking automated systems that not only enhance efficiency but also adapt to the rapid pace of consumer demands. One significant trend is the rise of smart packaging solutions, which utilize sensors and IoT technology to provide real-time data on product condition and shelf life. This connectivity allows businesses to respond swiftly to inventory needs, reducing waste and optimizing logistics.

Additionally, advancements in robotics and artificial intelligence are reshaping how packaging machines operate within production lines. With the ability to learn and adapt, robotic systems can handle a variety of products and packaging formats with precision. This flexibility is crucial in a market where personalization and customization are becoming standard expectations. Furthermore, eco-friendly packaging solutions are gaining traction, driven by a global push for sustainability. Innovations in materials, such as biodegradable plastics and reusable packaging systems, are not only addressing environmental concerns but also paving the way for companies to enhance their brand image and appeal to environmentally conscious consumers.