Maximizing Efficiency with Innovative Shrink Wrap Systems in Packaging Industry Trends

In the rapidly evolving packaging industry, maximizing efficiency is paramount, and innovative Shrink Wrap Systems are at the forefront of this transformation. These advanced systems not only enhance productivity but also adapt to the growing demands for sustainability and customization. By integrating cutting-edge technology with efficient shrink wrapping processes, companies are finding new ways to streamline operations while reducing material waste.

This article will explore the latest trends in packaging that revolve around the optimization of Shrink Wrap Systems, showcasing the benefits they bring to manufacturers and consumers alike. From improved supply chain logistics to enhanced product protection, understanding how to leverage these innovative solutions can lead to significant gains in efficiency and profitability. As we delve deeper into these industry trends, we will highlight the best practices and digital advancements shaping the future of packaging.

Embracing New Technologies in Shrink Wrap Systems

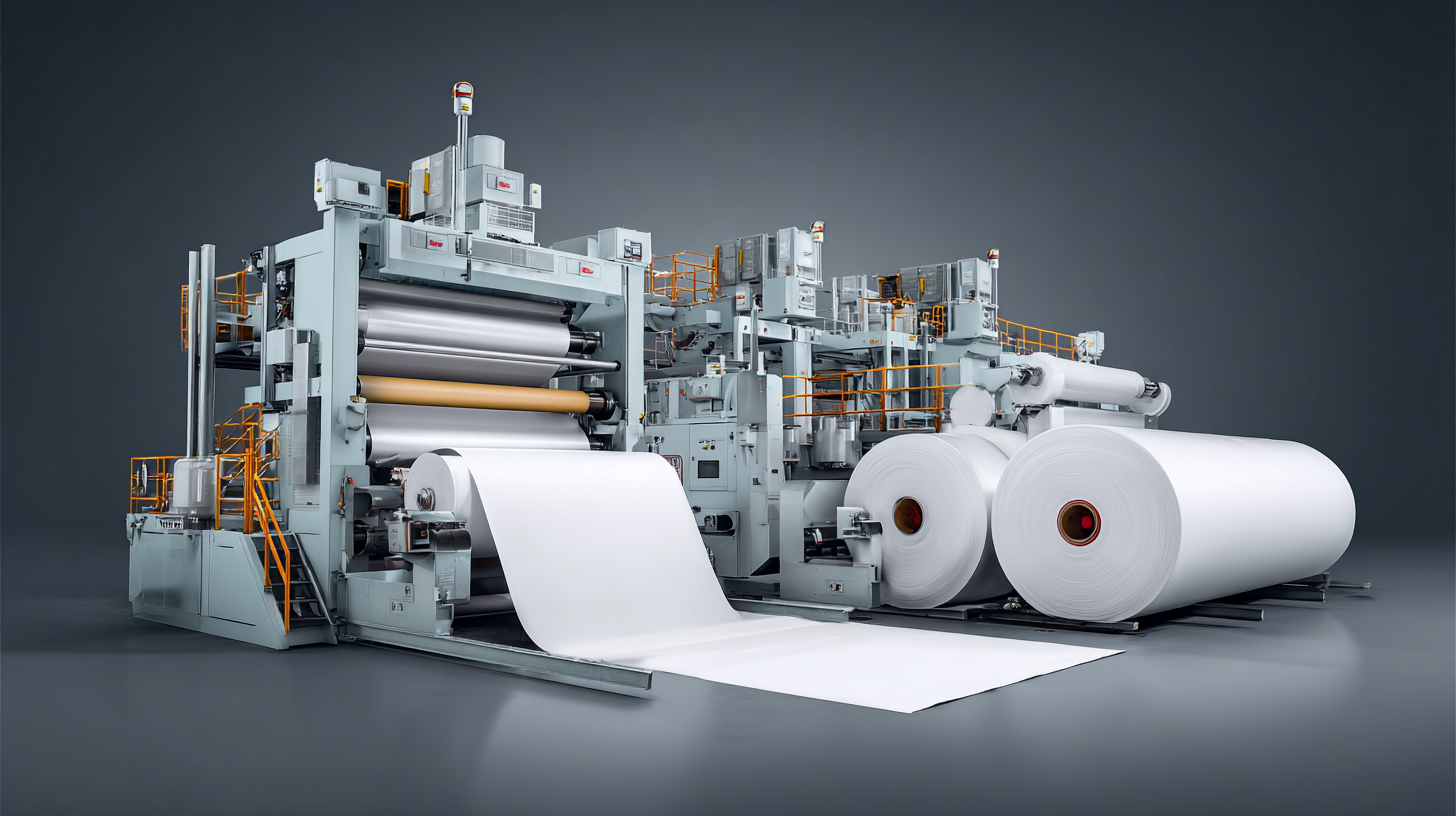

Innovative shrink wrap systems are evolving rapidly, aligning with the need for enhanced efficiency in the packaging industry. As technologies advance, businesses are increasingly embracing new materials and methods to optimize their packaging processes. From pallet wraps to versatile pouches, companies are discovering that investing in state-of-the-art shrink wrap solutions not only minimizes waste but also improves product protection during shipment.

Incorporating sustainable materials is crucial. The rise of post-consumer recycled (PCR) content in packaging options allows companies to address plastic pollution while maintaining brand integrity. By shifting towards green packaging solutions, businesses can engage environmentally-conscious consumers and contribute to broader sustainability efforts. This trend not only reflects a commitment to corporate responsibility but also resonates with modern consumer expectations.

**Tips:** When choosing shrink wrap materials, consider options that allow for easy recyclability or contain PCR content to bolster your sustainability goals. Regularly assess your packaging processes and explore innovations that could streamline operations, reduce costs, and enhance the performance of your products in transit.

Maximizing Efficiency with Innovative Shrink Wrap Systems in Packaging Industry Trends

| Shrink Wrap System Type | Efficiency Rating (%) | Average Cycle Time (seconds) | Energy Consumption (kWh) | Sustainability Index |

|---|---|---|---|---|

| Automatic System | 92 | 6 | 1.5 | 8.5 |

| Semi-Automatic System | 85 | 10 | 2.2 | 7.0 |

| Manual System | 75 | 15 | 3.5 | 5.5 |

| Integrated System | 90 | 7 | 1.7 | 9.0 |

| High-Speed Shrink Wrapper | 95 | 5 | 1.3 | 9.5 |

Sustainability Practices in Modern Packaging Trends

Sustainability has become a paramount concern in the modern packaging industry, reflecting a significant shift towards eco-friendly practices. Brands are increasingly blending ethics with innovative designs, as seen in the transformation of luxury personal care packaging. The move from traditional materials like glass to sustainable options illustrates how consumer preferences are evolving, prioritizing environmental responsibility alongside exclusivity and novelty.

In the food industry, sustainability-driven transformations are taking center stage, with organizations recognizing the critical role of packaging in minimizing environmental impact. Initiatives such as national consultations on sustainable packaging highlight the urgency of adopting greener practices. Moreover, the agriculture sector is also embracing sustainability, with packaging suppliers focusing on eco-friendly materials and innovative types to meet the rising demand for responsible solutions. As industries progress towards these practices, the growth of the green packaging market underscores the importance of adapting to consumer awareness and regulatory frameworks aimed at enhancing sustainability in packaging methodologies.

Cost-Effectiveness of Innovative Shrink Wrap Solutions

In the dynamic landscape of the packaging industry, innovative shrink wrap solutions are emerging as a critical component for maximizing efficiency and cost-effectiveness. The global shrink wrap market is projected to grow from an estimated $12.27 billion in 2025 to approximately $18.85 billion by 2032, reflecting a robust compound annual growth rate (CAGR) of 6.32%. This growth is driven by the increasing demand for versatile and affordable packaging options that meet both consumer preferences and sustainability goals.

As companies strive to enhance their packaging methods, the adoption of innovative shrink wrap systems allows for significant cost savings while providing superior product protection. For instance, the growing focus on returnable transport packaging (RTP) demonstrates a shift toward cost-effective logistics solutions. The RTP market is estimated to reach $25.25 billion by 2025 and further grow to $35 billion by 2033, with a CAGR of 4.35%. These trends indicate that businesses investing in advanced shrink wrap technologies can not only streamline their operations but also cater to the increasing consumer demand for eco-friendly and efficient packaging solutions.

Enhancing Product Protection through Advanced Shrink Wrap Techniques

In the fast-evolving packaging industry, advanced shrink wrap techniques are at the forefront of enhancing product protection. These innovative systems not only shield products from physical damage but also play a crucial role in maintaining their integrity throughout the supply chain. By utilizing high-quality materials and precise application methods, businesses can ensure that their products arrive in optimal condition, reducing waste and increasing customer satisfaction.

One effective tip for maximizing the benefits of shrink wrap is to choose the right film thickness for your specific products. Thicker films provide superior puncture resistance and are ideal for heavy or sharp-edged items, while thinner wraps can effectively secure lighter products without unnecessary bulk. Additionally, investing in high-performance shrink wrap machinery can significantly streamline the packaging process, leading to improved efficiency and consistency in product presentation.

Another crucial point to consider is the importance of proper sealing techniques. Ensuring that the shrink wrap is tightly sealed around the product prevents contamination and moisture ingress, ultimately protecting the items from spoilage during transportation. Regular maintenance of the sealing equipment can also enhance performance, allowing companies to achieve a reliable, high-quality seal every time.

Future Trends in Shrink Wrap Systems for Efficient Packaging

The future of shrink wrap systems in the packaging industry is poised for significant transformation, driven by advancements in technology and the rising demand for efficiency. According to recent industry analysis, the vacuum packaging market is expected to witness substantial growth, with a projected market value of USD 8.2383 billion by 2024, surging to approximately USD 13.408 billion by 2032, reflecting a compound annual growth rate of 6.28%. This growth is indicative of the increasing emphasis on sustainable and efficient packaging solutions across various sectors, including food, pharmaceuticals, and consumer goods.

As the packaging landscape evolves, innovative shrink wrap systems are becoming integral in maximizing operational efficiency. The upcoming swop 2024 event in Shanghai will showcase cutting-edge technologies that support this shift towards smart and eco-friendly packaging. Industry leaders are increasingly focused on integrating automation and sustainable materials into their packaging processes, which not only enhance productivity but also align with global sustainability goals. The combination of intelligent manufacturing and advanced shrink wrap technologies promises to redefine packaging standards, making them more adaptable to future market needs.

Related Posts

-

Top Strategies for Enhancing Efficiency with Shrink Wrap Systems

-

Exploring the Impact of Shrink Wrapping Technology on Packaging Efficiency and Cost Reduction in Global Supply Chains

-

2025 Insights on Best Shrink Wrapper Trends and Performance Comparison

-

7 Tips to Choose the Best Heat Shrink Wrap Machine for Your Global Business Needs

-

How to Identify Reliable Suppliers for the Best Heat Shrink Wrap Machine Globally

-

Top Strategies for Optimizing Your Packaging Equipment Efficiency