How to Optimize Your Production Line with Advanced Cartoning Machines: A Data-Driven Approach

In today's fast-paced manufacturing landscape, optimizing production lines is crucial for enhancing efficiency and reducing costs. A key component in this quest for optimization is the use of advanced cartoning machines, which have been shown to significantly streamline packaging processes. According to a report by Smithers Pira, the global demand for automated packaging equipment is expected to grow at a CAGR of 4.3% from 2020 to 2025, with cartoning machines playing a vital role in this transformation. These machines not only increase throughput by up to 30% but also improve accuracy and product safety, reducing material waste and operational downtime. As manufacturers strive to meet escalating consumer demands while maintaining competitiveness, a data-driven approach to integrating cartoning machines into production lines can provide substantial returns on investment, paving the way for more efficient and sustainable manufacturing practices.

Understanding the Role of Cartoning Machines in Modern Production Lines

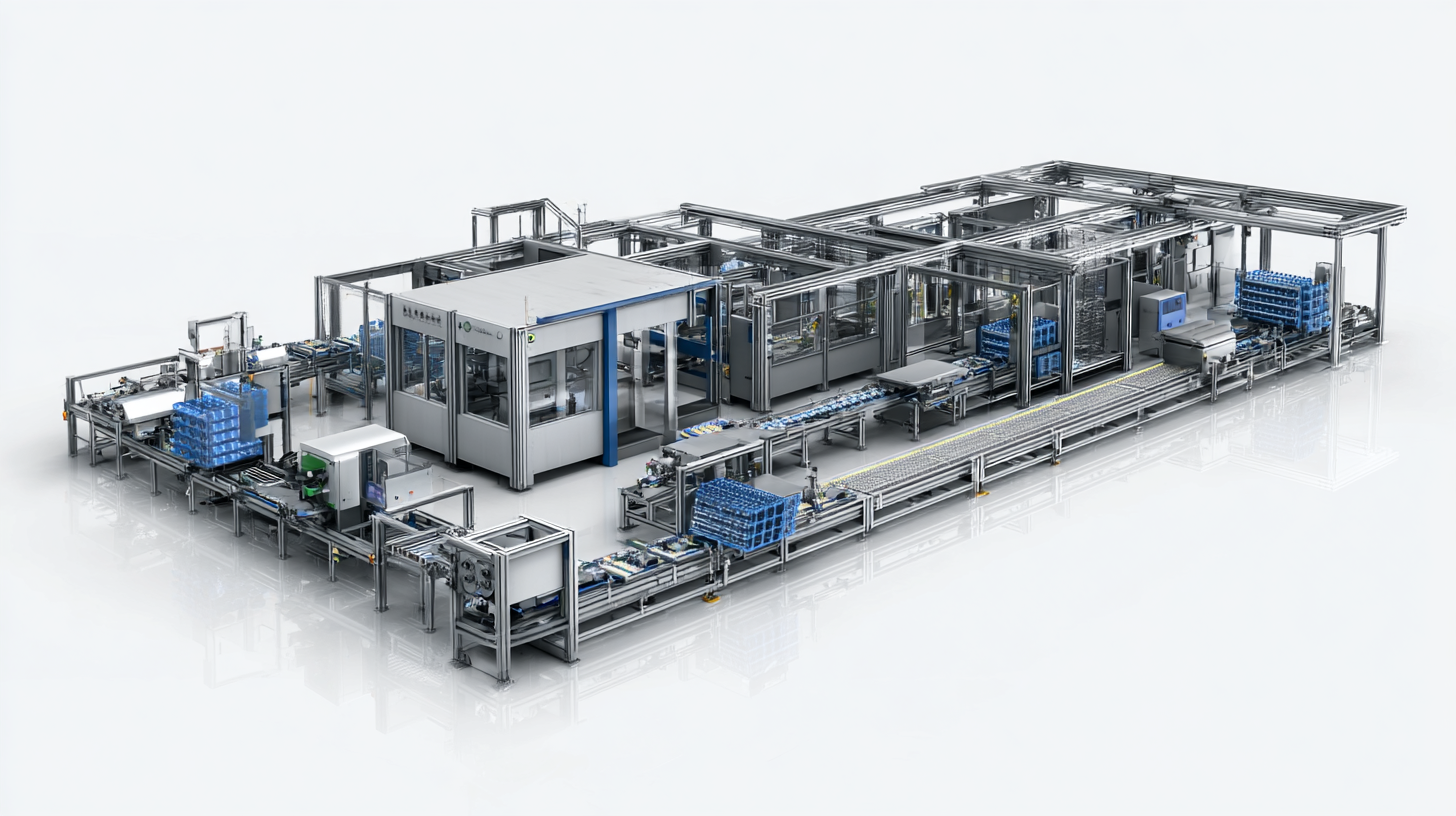

In modern production lines, cartoning machines play a pivotal role in enhancing efficiency and ensuring consistent quality. These machines are integral to the packaging process, automating the packing of products into cartons, which not only speeds up production but also minimizes human error. The use of advanced cartoning machines streamlines operations, providing manufacturers with the ability to handle various product sizes and shapes without compromising speed or accuracy.

Understanding the workflow of cartoning machines is crucial for optimizing production lines. These machines are designed to integrate seamlessly with upstream processes, such as filling and labeling, enabling a continuous flow of goods. By utilizing data-driven strategies, businesses can monitor machine performance, track throughput, and make informed adjustments to operations. This proactive approach not only maximizes productivity but also improves the overall reliability of the packaging process, ultimately leading to enhanced customer satisfaction and reduced operational costs.

Comparing Different Types of Cartoning Machines for Optimal Performance

When optimizing production lines, selecting the right cartoning machine is paramount. Different types of cartoning machines—such as vertical, horizontal, and wrap-around—offer varying efficiencies and capabilities. According to a recent report by Smithers Pira, companies can increase their output by up to 30% by transitioning from traditional cartoning methods to advanced machine technology. This is particularly noticeable in high-speed environments where consistent quality and speed are critical.

To effectively compare these machine types, assess your production volume, the size and shape of products, and desired throughput. For instance, horizontal cartoning machines are often ideal for high-speed operations, making them suitable for products like beverages and packaged snacks. In contrast, vertical machines are more flexible for smaller, varied product sizes.

Tip: Conduct a thorough analysis of your product specifications and production goals before investing. Testing different machine types in pilot runs can provide valuable insights into which system maximizes efficiency.

Tip: Don’t overlook the importance of after-sales service. A machine’s operational efficiency can diminish without proper maintenance, and investing in a manufacturer known for robust support can significantly enhance long-term performance.

Evaluating the Cost-Benefit of Advanced Cartoning Solutions

In today's competitive market, businesses are constantly seeking ways to enhance efficiency and reduce costs. Evaluating the cost-benefit of advanced cartoning solutions is crucial for manufacturers aiming to optimize their production lines. By analyzing the initial investment against potential savings and increased productivity, companies can make informed decisions. Advanced cartoning machines often feature automation capabilities that significantly streamline the packaging process, minimizing labor costs and reducing errors associated with manual handling.

Furthermore, the longevity and reliability of these machines can lead to lower maintenance costs over time. Integrating advanced cartoning machines allows for faster throughput, which translates into higher output and profitability. By employing data analytics, manufacturers can measure performance metrics, such as speed, waste reduction, and energy usage, highlighting the tangible benefits of upgrading to state-of-the-art cartoning solutions. Ultimately, a data-driven approach ensures that businesses can not only justify their investment but also position themselves for growth in a rapidly evolving industry.

Integrating Automation: Enhancing Efficiency with Smart Cartoning Systems

In today's competitive manufacturing landscape, integrating automation into your production line is more crucial than ever. Advanced cartoning systems equipped with smart technology can significantly enhance efficiency and accuracy. These systems utilize intelligent software to monitor processes in real-time, allowing for quick adjustments to optimize output. By employing sensors and data analytics, manufacturers can identify bottlenecks and streamline operations, ultimately leading to faster turnaround times and reduced labor costs.

Moreover, smart cartoning systems facilitate better resource management. With precise tracking of materials and automated inventory control, manufacturers can minimize waste and ensure that production runs smoothly without disruptions. Flexible configurations allow these machines to adapt to various product types, making it easier for businesses to respond to changing market demands. Investing in such technology not only boosts overall productivity but also positions companies to meet future challenges with greater agility and resilience.

Case Studies: Successful Implementations of Cartoning Machine Alternatives

When it comes to optimizing production lines, the implementation of advanced cartoning machines can lead to significant improvements in efficiency and throughput. In our case studies, we will explore successful implementations of alternative cartoning solutions that have transformed manufacturing processes across various industries. One notable example is a food packaging company that replaced their manual cartoning system with a fully automated solution. This shift not only reduced labor costs but also increased packaging speed by 300%, allowing the company to meet growing consumer demand without compromising quality.

Another compelling case study involves a pharmaceutical manufacturer that faced challenges with product consistency and compliance. By investing in a robotic cartoning machine, they streamlined their packaging operations while ensuring precise placement and sealing of cartons. The upgrade resulted in a 40% reduction in packaging errors and improved traceability, which is critical in the highly regulated pharmaceutical sector. These examples underscore the importance of leveraging data-driven approaches and innovative technologies to enhance production lines and maintain a competitive edge in the market.

How to Optimize Your Production Line with Advanced Cartoning Machines: A Data-Driven Approach - Case Studies: Successful Implementations of Cartoning Machine Alternatives

| Case Study | Production Increase (%) | Cost Reduction (%) | Product Variability | Return on Investment (ROI) | Implementation Time (months) |

|---|---|---|---|---|---|

| Case Study A | 25% | 15% | Low | 200% | 6 |

| Case Study B | 30% | 20% | Medium | 180% | 5 |

| Case Study C | 40% | 25% | High | 250% | 7 |

| Case Study D | 20% | 10% | Low | 150% | 4 |

Related Posts

-

Exploring the Future of Food Packaging Innovations and Their Impact on Global Supply Chains

-

Mastering the Best Intermittent Motion Packaging Machine for Your Business Needs

-

Unlocking Global Opportunities at the 137th Canton Fair with Innovative Shrink Wrap Film Solutions

-

7 Key Advantages of Choosing the Best Food Packaging for Your Business

-

Top Strategies for Enhancing Efficiency with Shrink Wrap Systems

-

2025 Global Trends in Shrink Wrap Machines 5 Key Innovations to Watch